With a name like "replicator", one might imagine that the odd,

box-shaped device sitting in ICTP's Science Dissemination Unit's

(SDU) laboratory was a low-tech version of the matter converters

used by the intrepid crew of the Starship Enterprise.

However, reaching that part of the technological universe may take

a few more years. The "replicator " at ICTP is a

three-dimensional printer that can make solid objects out of

plastic. Using a digital model, the printer creates the objects

layer by layer with a molten liquid plastic.

At a seminar today (24 October), SDU's Carlo Fonda introduced this

new technology to the ICTP community. SDU has created the

innovative, low-cost EyA automated recording system for classrooms,

so it follows that they would be interested in new technologies

that could enhance science education.

After presenting an

overview of the development and costs of 3-D printers (they are

getting cheaper, which is good news for early adopters who may want

to purchase one of their own), Fonda talked about the uses, which

range from art to prosthetics to humanitarian projects in the

developing world. "Students can print out molecules to discover

their complex structures," explained Fonda.

After presenting an

overview of the development and costs of 3-D printers (they are

getting cheaper, which is good news for early adopters who may want

to purchase one of their own), Fonda talked about the uses, which

range from art to prosthetics to humanitarian projects in the

developing world. "Students can print out molecules to discover

their complex structures," explained Fonda.

Fonda believes that 3-D printing has the capability to popularize

and democratize science. "I would like to bring a 3-D printer to

Africa," said Fonda, who has travelled extensively through the

continent to teach hands-on courses on wireless networking and

other topics.

For a video of today's demonstration, please see ictp.tv.

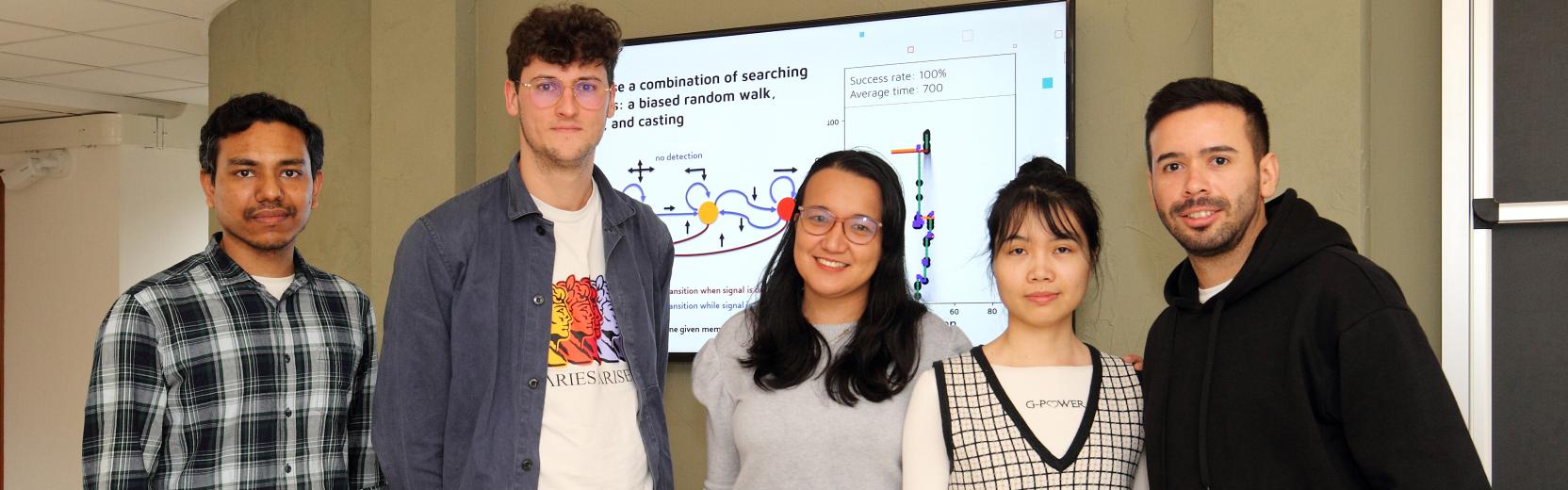

Photos at right: In top photo, Carlo Fonda (right) demonstrates a 3-D printer. Below, seminar attendees admire 3-D printer sample objects.